The function of safeguarding devices and guards is to protect operators from dangerous moving parts and injuries. Employees working in the general work area should also be adequately protected from flying materials. The use of administrative and engineering controls is the best way to control hazards. Moving machine parts can lead to severe workplace injuries. Following are 4 general methods of safeguarding machinery and equipment:

1. Devices

There are situations where barrier guards are not considered as a practical solution. For instance, a barrier guard cannot be applied to operations where ejection of parts is required. This is where various devices come into play. Some of them are:

Safety control devices

Safety control devices shutdown a machine in emergency situations. Trip rods, two-hand controls, and pressure-sensitive body bars are some of the examples of safety control devices.

Sensing devices

Sensor technology can certainly improve the safety standards of a manufacturing facility. Presence sensing devices shut off a machine when someone enters the danger area.

Physical restraint devices

As the name suggests, physical restraint devices such as a cable or strap limit the movement of an operator so that he cannot reach into the danger area.

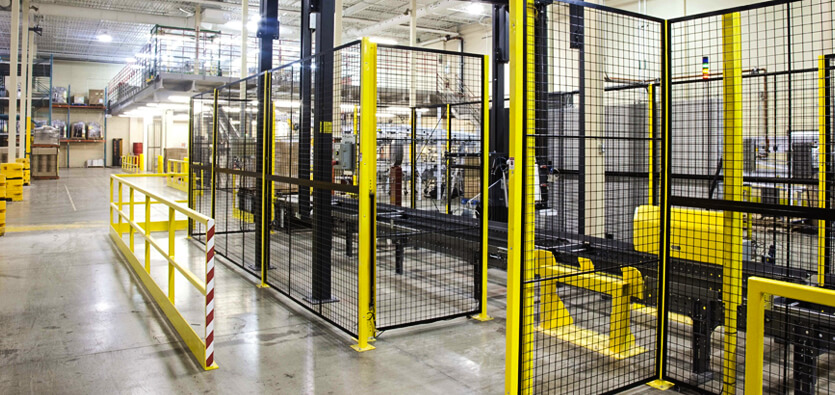

2. Guards

There is a variety of guards used to prevent workers from physically reaching into a restricted area. Fixed guards, permanently fixed parts, are used widely to protect workers from the power transmission equipment. It is often recommended to use fixed guards that cannot be removed by operators. Adjustable guards are flexible and can accommodate various sizes of material. There are also self-adjustable guards that allow barriers to open or close depending on the movement of material.

3. Distance

This technique is about positioning the dangerous part of machines in such a way that they are not accessible to the worker during the normal operation of the machine. For example, it can be done by placing the dangerous moving parts against a fence or wall. To implement this technique, it is essential to conduct a thorough hazard analysis.

4. Awareness barriers

Awareness barriers do not provide protection against hazards; rather, they function as a reminder to workers that they are entering into a dangerous area. This is a useful technique but cannot ensure complete safety. Continual exposure to the hazard demands more than just awareness barriers.

It is of utmost importance to develop a safe working environment where employees can work efficiently and with a peace of mind. Machine safeguards not only improve safety conditions but also improve the productivity of workers. Therefore, carry out a thorough evaluation and find out which areas in your manufacturing facility need to be safeguarded.

BP Automation is an automation solution provider renowned for its efficient and cost effective engineering solutions in Canada. We design and manufacture machine safeguards and devices to help manufacturers develop a hazard-free working environment. Consult our engineering team to know more about our automation products and services.