Technological progress has helped lift people out of the poverty cycle, raised standards of living and improved the way manufacturing processes were performed. Development in the industrial technology has already made it feasible for manufacturers to achieve the higher level of growth and productivity by adopting smart machines. The increased use of industrial robots is the one indication that automation can produce the finest products in short periods of time. The automotive industry accounts for almost half of the industrial robots sold in Canada. Metal and machinery manufacturing industries come after auto manufacturing.

The impact of automation can also be measured in terms of the number of robots per 10,000 workers or, in other words, robot density. This way of measuring progress suggests that South Korea is leading the chart followed by Japan, Germany, and Canada. The loss of human labor is one of the common fears people express about the growing use of robots. However, the development of novel means of production can only improve the employment situation in a region.

The use of advanced manufacturing tools does not create higher unemployment. On the contrary, it creates job opportunities for skilled labor. Currently, there is a considerable shortage of skilled labor, people who can work with highly sophisticated automated working environments. Despite the unprecedented advancements in automation technology, there are some manufacturing tasks that cannot be performed by machines and that human intervention is inevitable.

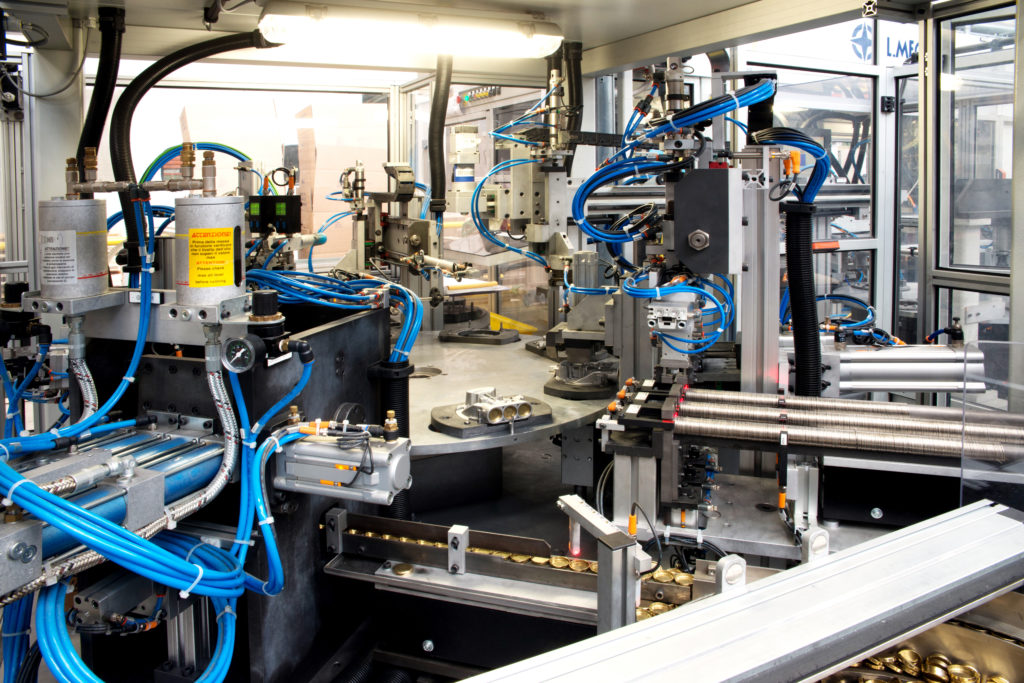

The decision to invest in new technologies depends on a number of factors: the cost of machines, competitive pressure, ability to operate and maintain machines, potential benefits, to name a few. Small businesses sometimes cannot afford to go for newly invented manufacturing techniques. Some technologies require years to reach their full potential and become commercially viable. However, there are fully developed and economically viable technologies such as automated welding machines that are within the reach of small metal fabrication shops. Robotic welding systems get the job done quickly and produce great results in terms of precision, speed, and quality. Make sure you are following the trends that will dominate the manufacturing industry in coming years.

Keeping in mind the intensity of competition and demand for high-quality products, automation is the only solution that can help you meet the market requirements. Automated machines will not only increase your productivity but also improve your safety standards. Therefore, stay ahead of the competition and use automation as a solid way to dominate your market.

Related: How to improve productivity and profitability of your manufacturing processes?

BP Automation is an automation engineering company in Edmonton that designs and manufactures automated solutions for various manufacturing processes such as welding, pipe cladding, prototype development, assembling, precision machining, material handling, food processing, metal fabrication, to name a few. We have resources and in-house capabilities to make your complex manufacturing processes lean and highly profitable. Feel free to discuss your manufacturing problems and see how we can help to resolve them.